CASA International invests in the future

STILL and Dematic deliver automation for new European distribution centre.

Tasks: Omnichannel markets require to centralise all European logistics activities for more than 500 stores in Europe

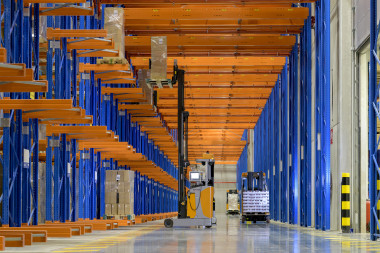

Solution: Largely automated distribution centre with 50,000 m2 and 65,000 pallets. Together with twelve automated STILL series trucks.

Products: Full analysis of the material and information flow. Planning and realization of a creative storage and racking concept for maximum storage capacity in combination with seven automated STILL FM-X reach trucks and five automated STILL MX-X narrow aisle trucks.

Intralogistics specialist STILL has automated the new CASA European distribution centre in Olen, Belgium, in cooperation with its KION Group affiliate Dematic. A total of twelve automated STILL series trucks provide flawless, fast, clean and silent logistics, whereby the interior retail chain is absolutely ready for the future.

In 2017, CASA International, an international interior retail chain with more than 500 subsidiaries in nine European countries, implemented its new strategic master plan, which is known as CASA 2020. A logistics master plan that is geared towards the future was also rolled out at the same time. „All of our logistics activities are thereby centralised in a new, largely automated European DC,“ explained Bart Dauwen, warehouse manager at CASA International.

Essential investment

The new building in Olen, Belgium, measures more than 50,000 m2 and it can hold 65,000 pallets. The total investment for project amounts to € 35 million, but according to Dauwen, this was an absolutely necessary investment, partly in view of the developments in e-commerce. „Our market is increasingly becoming an omnichannel market. In order to maintain a strong position in this changing market in the future, it is essential to invest in a logistics organisation that performs well. With this new EDC, we are in a position to distribute our range in a more ecological and efficient manner to more than 500 stores throughout Europe,“ said the warehouse manager.

Reliable and flexible

Following economic growth and an increasing shortage in the labour market, it is becoming an even greater challenge for logistics companies to find qualified personnel. With this investment in automation, we can improve the continuity of the flow of our goods, while also increasing our productivity at the same time,“ continued Dauwen. „Moreover, our flexibility also improves. Automation clears the way to a fully continuous process that operates 24 hours a day, 7 days a week.“

Mainly sea containers

The STILL and Dematic solution provides automatic supply of the order picking area, transportation of pallets to and from the bulk warehouse and the loading and unloading of goods at the warehouse. After goods have been delivered - mainly via sea containers - the boxes are repacked by warehouse employees on pallets. The pallets are transported by a conveyor system to an automatic wrapping station, after which they are taken to a fully automatic control station. Here the goods are once again checked and registered, after which the solution from STILL and Dematic automatically comes into play.

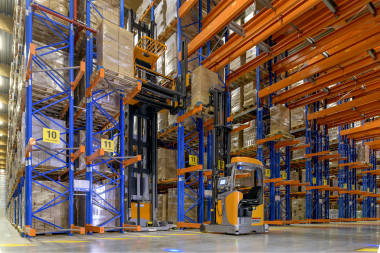

Twelve trucks

A total of twelve warehouse trucks are used; 7 STILL FM-X reach trucks, for the supply of pallets to the bulk warehouse, and 5 MX-X narrow aisle trucks for fully automatic loading and unloading in the bulk warehouse with 32 passageways. When the goods have to be transported to the manual order picking area, one of the seven FM-X reach trucks retrieves the pallet from a buffer position at the end of the racks, and then places it on one of the two conveyor tracks that lead to the order picking point.

„Our FM-X and the MX-X trucks are fully automated with technology from our affiliate Dematic, with whom we cooperate in AGV projects with standard warehouse trucks in Europe“, declared Luc de Boes, Head of Benelux Sales at STILL. „This allows us to offer CASA a complete solution from a single source.“

Completely automated

The trucks are provided by Dematic with Automation Pack and the AGV management-software. „They receive their orders from the AGV management-software, which is linked to the customer‘s warehouse management system so that they can drive and lift autonomously,“ added Yves Gazin, strategic solutions manager at Dematic. Charging of the batteries, including interim charging, is also fully automated. When loading is necessary or desirable, the truck control system transmits this and the truck drives on its own to the charging station, where the battery is charged or recharged through special contact points. The trucks are equipped with various sensors to prevent collisions and to guarantee the safety of pedestrians in the warehouse. The reach trucks are also equipped with STILL SafetyLight that project a bright blue spotlight on the floor in the direction of travel of the truck, so that pedestrians can receive an additional alert that a truck is approaching.

Very content

According to De Boes, to be able to guarantee the success of an automation project such as this, it is essential as an intralogistics provider, that you know the KPIs of the customer and that you understand what they want: „Based on a thorough analysis, we have designed and implemented a solution together with the customer that meets all of their wishes and requirements.“ Gazin even calls it a textbook example of how an automation project should be: „Everyone knew exactly what to do. Clear agreements, short lines and the experience and expertise of all those involved formed the cornerstones of this success.“

The strategic solutions manager knows that it is only natural for the costs and return on investment to be taken into account, especially in the case of automation projects. The fact that the automated trucks last significantly longer than manually operated trucks plays a major role in this regard. „But,“ continued Gazin, „The real value of this high-quality solution lies in its flexibility. Logistics flows run flawlessly, cleanly, quietly and quickly. You can also see that when you walk through the warehouse. And that brings peace in an otherwise complex environment. It is a pleasant environment to work in.“

Warehouse manager Dauwen nodded with satisfaction. „We are very content about cooperation with STILL and Dematic,“ he concluded. „They have implemented the project within the required time. Ongoing operations have also been minimally affected.“